- Improving casting quality: the advantages of bauxite

- The high-temperature charm of bauxite for refractory sand

- Bauxite: High-temperature protection for welding rods

- Bauxite: the secret weapon of cast iron coatings

- Bauxite: The core component of refractory castables

- Improve casting quality, the secret of bauxite

- Bauxite promotes technological innovation in lost foam casting

- Bauxite for blast furnace smelting: Selection criteria revealed

- Bauxite: the key material for lost foam casting

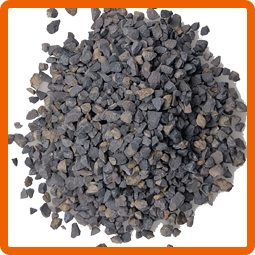

Rotary Kiln Bauxite

Rotary kiln bauxite

As the name suggests, rotary kiln bauxite is the bauxite produced by rotary kiln. The selected high-quality bauxite ore is loaded into the tunnel kiln. As the kiln body rotates slowly and continuously, the ore gradually passes through the preheating zone, sintering zone and cooling zone, and finally becomes calcined uniform and dense bauxite. Rotary kiln bauxite is used mainly for refractory industry as aggregate, it is the essential raw material for high quality refractory product, such as corundum brick, Zircon slide gate block.

Available grain size:

5-30mm; 0-1mm; 1-3mm; 3-5mm; 5-8mm; 80mesh; 100mesh; 200mesh; 325mesh.

Package

1MT Jumbo bag

Standard exporting package for sea transportation or air delivery

Special packing requirement is acceptable

Data sheet for Common Models

24-HOUR SERVICE, SPECIALLY FOR YOU

Email: info@sinocean.ltd

Tel: +86-371-55970121

Fax:+86-+86-371-66684099